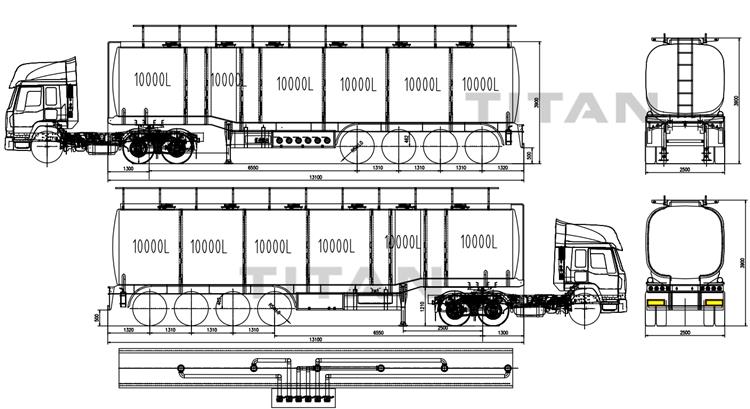

Thank you to our Mozambican customers for choosing TITAN. The machine chosen by this customer is our most popular fuel tanker trailer. Since the customer chooses 6 compartment of 60,000 liters fuel tanker trailer. So the thickness of the fuel tank is very important, which has a great impact on the tanker trailer, we need to use 5mm or 6mm high strength steel, especially when transporting a large amount of diesel/ when gasoline.

And a manhole and a drain valve are arranged in the accessories of the tank body. Fuel tanker trailers are mainly used to transport liquids and oils. Generally made of carbon steel plate, it can also be made of aluminum alloy, stainless steel and other materials.

The 60,000 liters fuel tanker trailer has plenty of strength. The 60,000 liters fuel tanker trailer has shock plates inside. Considering the road conditions, especially the African market, our 60,000 liters fuel tanker trailer is twist-resistant, shock-resistant and bump-resistant, making your transportation safe.

Since the liquid transported by the fuel tanker trailer will be flammable and explosive, the risk factor is very high. Therefore, in order to ensure the quality and safety, it must be checked and maintained regularly. Common defects and detection methods of tanks of hazardous chemicals transport vehicles.

60,000 Liters Capacity Fuel Tanker Trailer for Sale In Mozambique

60,000 Liters Capacity Fuel Tanker Trailer for Sale In Mozambique

1. Fuel tanker trailer wall thickness is not up to standard

Because many manufacturers do not implement the standard when they manufacture 60,000 liters fuel tanker trailer, there are no special regular inspection rules, and the management of the user is not in place, such transportation accidents can easily lead to combustion and explosion, emit toxic and harmful gases, and have great social impact.

A large number of casualties, serious environmental damage, and the difficulty of rescue pose a serious threat to social and public security. Therefore, it is very important to strengthen the regular inspection of fuel tanker trailer, standardize inspection work behavior, and ensure the quality of inspection work.

The thickness of 60,000 liters fuel tanker trailer is the basis for the strength of the tank and the fundamental guarantee for the safe operation of the 4 axle fuel tanker trailer. Therefore, accurately grasping the wall thickness of the tank is a very critical link in the regular inspection of the atmospheric tank.

60,000 Liters Capacity Fuel Tanker Trailer for Sale In Mozambique

60,000 Liters Capacity Fuel Tanker Trailer for Sale In Mozambique

Method for detecting wall thickness of fuel tanker trailer

During the inspection, great attention should be paid to the detection of the thickness of the tank wall. The actual thickness of the tank body is measured by an ultrasonic thickness gauge. First, it is judged whether it meets the requirements of the minimum wall thickness of the tank body.

Second, the corrosion rate of the tank material is estimated, and then the fuel Checks the corrosion and thinning condition of tanker trailer for sale tank. The parts of the wall thickness measurement generally choose the parts where the liquid level fluctuates frequently, the bottom of the tank where the medium stays, the parts where the wall thickness is reduced during processing and forming, and the parts that are prone to wear and deformation during operation.

The mechanical damage, pitting corrosion and local corrosion of the fuel tanker trailer for sale found in the inspection shall be eliminated by grinding. If the measured residual wall thickness is checked for strength according to the original design standard, if the strength requirements cannot be met, it shall be rated as unqualified. For tanks with uniform corrosion and insufficient thickness, the strength shall be checked according to the remaining wall thickness.

If the strength requirements cannot be met, it shall also be rated as unqualified. Tanker trailers for sale that are rated as unqualified shall not be used.

60,000 Liters Capacity Fuel Tanker Trailer for Sale In Mozambique

60,000 Liters Capacity Fuel Tanker Trailer for Sale In Mozambique

2. The anti-wave plate in the tank falls off

It is an effective measure to deal with the medium shock by setting the anti-wave board in the fuel tanker trailer for sale. During the operation of the fuel tanker for sale, the anti-wave board is used as a reinforcing component to directly bear the impact of the medium fluctuation.

Usually, the anti-wave board and the tank body are filled with fillet welding. seam connection. When the fuel tanker trailer for sale is running, the liquid in the tank also shakes due to bumps and frequent changes in speed.

Under the long-term action of this alternating load, the anti-wave board will appear defects such as erosion and wear, welding seam desoldering, deformation and distortion, penetrating cracking, etc., and some even the whole piece is desoldering or cracking and falling off. The liquid moves back and forth up and down, directly impacting the tank, causing the tank to wear and thin, which seriously affects driving safety.

Method of detecting wave-proof board

During the inspection, the inspection of the anti-wave board in the tank should be strengthened to confirm that its use condition is stable and firmly fixed, and the inspection of the inner and outer surfaces of the joint between the anti-wave board and the tank should be emphasized.

If necessary, surface non-destructive testing should be added. Serious defects such as thinness, surface cracks, deformation and twisting, and loose bolts that endanger the safe operation of the tank should be repaired in time, otherwise the 4 axle tanker trailer price is prohibited from being used.

60,000 Liters Capacity Fuel Tanker Trailer for Sale In Mozambique

60,000 Liters Capacity Fuel Tanker Trailer for Sale In Mozambique

3. Beam connection weld crack

The welding seam between the tank body and the frame or the welding seam between the saddle backing plate and the chassis is the main part that bears the stress load during the operation of the tanker trailer price. , the main reasons are as follows.

When the tank body and the chassis are welded, there are defects such as incomplete penetration, incomplete fusion, slag inclusion, and undercut. When the 60,000 liters capacity fuel tanker trailer operates, these defects appear stress concentration under the action of complex stress and become the cracks of weld cracking. source.

In order to maximize economic benefits, the overload phenomenon is very serious. The overload causes the centrifugal force of the 60,000 liters capacity fuel tanker trailer to increase when turning and going up and down slopes, and the inertia increases during acceleration and deceleration. There is stress concentration in itself, and weld cracking is easy to occur.

Some logistics companies have privately modified the tank body, modified hydrochloric acid or sulfuric acid with a high density, resulting in the actual loading quality of the tanker far exceeding the nuclear load quality, and the vehicle carrying capacity is seriously insufficient, which has become a major hidden danger for safe operation.

During the inspection, the tanker was found many times. There is a crack at the connection between the tank and the frame, which is directly related to the private transformation.

Individual tank car owners, in order to do more material, privately modified and lengthened the tank body, resulting in the phenomenon of "small car with large tank". Due to the irregular modification, the welding seam between the tank body and the base was not lengthened accordingly, plus the heavy pressure and operation of the medium The stress concentration in the joint can easily cause cracking of the connection weld here.\

60,000 Liters Capacity Fuel Tanker Trailer for Sale In Mozambique

60,000 Liters Capacity Fuel Tanker Trailer for Sale In Mozambique

Check the girder method

During the inspection, the welding seam between the tank body and the chassis should be mainly checked, and the volume of the tank body should be preliminarily estimated by using the external dimensions of the tank body, and the “water volume” method should be used for proofreading.

Combined with the actual density of the medium, check the actual nuclear load quality of the tank car. , and indicate in the conclusion of the inspection report that the overload operation of the 60,000 liters capacity fuel tanker trailer will be avoided. Tank trucks with penetrating cracking of the girder should be judged as unqualified and can be put into use only after rectification and passing.