Customers Feedback of 4 Axle Low Loader Trailer.Dominican customer recently received a 4 axle low loader trailer, and are full of praise.

Dominican Customers Feedback of 4 Axle Low Loader Trailer for Sale

Dominican Customers Feedback of 4 Axle Low Loader Trailer for Sale

Due to certain force majeure factors, the customer's 4 axle low loader trailer was parked in Tianjin parking lot for more than a month before boarding the ship, and then drifted for two months before arriving in Dominica. It was also parked at the port for two months before customs clearance.

After two months of drifting at sea and 2 months of parking at the beach, the customer received the 4 axle low loader paint intact. The customer said that it exceeded expectations and was very satisfied with this purchase.

TITAN all semi trailer have professional staff to make a package, all of them were trained constantly. Please notice that to prevent the low loader trailer paint from being corroded by seawater to we spray a layer of wax on the surface of the lowboy trailer before shipping. And covering poncho to prevent the damp condition.

Customers Feedback of 4 Axle Low Loader Truck Trailer Price

Customers Feedback of 4 Axle Low Loader Truck Trailer Price

In addition, customers are very fond of TITAN's production, and only a standardized and rigorous production process can ensure the quality.

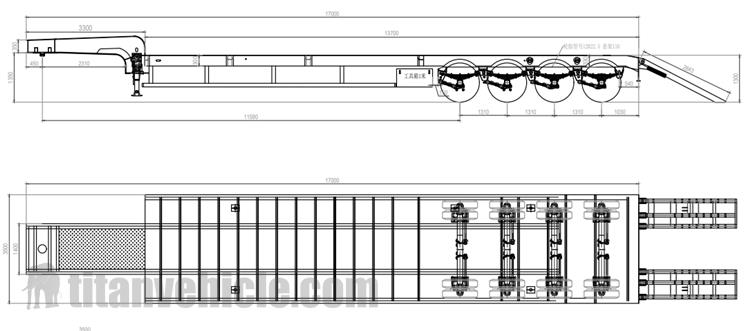

Before production produce drawings according to the needs of the user and the market, so that the technical parameters of the main 80 ton low loader trailer are matched, and then transferred to the manufacturing department.

1. Submerged arc welding beams, beams fixed

The second step is to fix the cut web and the upper and lower wing plates to weld points, and then weld the beam by submerged arc welding.

2. Opening, calibration beam, through beam

First cut out the web of the beam to cut out U-shaped holes through which the beams can pass, and then fix the welded I-beams in parallel. The result of comparing the beams is very important. If two I-beams have large parallel errors, very serious tire wear will occur.

Factory show of 80 Ton Low Loader Trailer

Factory show of 80 Ton Low Loader Trailer

3. Connect side beams, welding king pins

At this time, the 4 axle low bed trailer of the main beam is basically formed, only the side beams are welded to form the frame structure. And the traction pin traction plate is welded to the position required in the contract, the welding process is required to be high, otherwise, the lowbed truck trailer will be skewed.

4. Welding frame, welding suspension

At this time, the welding suspension must strictly control the size and maintain the squareness, otherwise it will cause 4 axle low loader for sale malaysia of tire wear. Low Loader Trailers use high-strength international steel material, the vehicle has a lightweight, and guarantees its anti-torsion, anti-vibration, anti-bump ability, and meets different load bearing capacity.

4 Axle Low Bed Trailer Product Process

4 Axle Low Bed Trailer Product Process

Low Loader Trailers are widely used, mainly for medium and long-distance freight transportation. Its frame is a beam-through structure, and the longitudinal beam adopts a straight and live gooseneck type. The height of the webs ranges from 400mm to 550mm, the longitudinal beams are welded by automatic submerged arc welding, the frame is shot blasted, and the beam penetrates the longitudinal beams and welds the whole.

When loading mechanical equipment on Low Loader Trailers, the mechanical equipment is usually loaded from the rear of the semi-trailer, that is, the mechanical equipment is moved from the rear wheel frame or the wheels are removed, and then the mechanical equipment is fixed on the semi trailer.

Low Loader Truck Trailer Manufacturer for Sale

Low Loader Truck Trailer Manufacturer for Sale